Your choice for Precision Investment Castings

Our Markets:

See Products Video

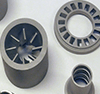

AMT is a leading manufacturer of precision investment castings used across a broad range of critical applications. Our customers are found in all key markets including: Aerospace, Power Generation, Medical, Industrial, Defense, and others.

What We Offer:

Proven expertise in manufacturing castings with intricate geometries, thin walls, exacting specifications and challenging requirements. Our Investment Castings Solutions will meet and exceed your expectations.

- Size: castings ranging from 0.25” to 10” with wall thickness as low as 0.020”

- Alloys: a full range of air melt alloys including Nickel, Cobalt, Aluminum and Copper based alloys as well as Stainless and Low Alloy Steels

- Supply Chain: offering finished products including machining and coatings as well as assembly operations where required

- Inventory programs: ensuring your castings are available when you need them!

Why AMT?

- Quality: Certified under AS9100D and ISO 9001:2015, AMT is also NADCAP accredited. Our fully integrated ERP system provides full lot traceability and real-time shop floor feedback.

- Service: From quotation inquiry and expedite request through technical support and final delivery, our Team’s responsiveness will exceed your expectations.

- Latest Technology: Including semi-automatic wax presses, 100% robotic shelling, an exclusive high speed infrared shell drying tunnel, best-in-class rapid prototyping 3D wax printer as well as a unique high-speed Automated Visual Inspection capabilities to meet our customer’s exacting requirements.

- Unique: AMT offers expertise using either the Shell Mold or the Solid Mold processes. This allows us to select the best process to meet your specific job requirements. See our Unique molding processes.

- Transfer tool: AMT is the preferred choice to develop new castings. In addition, with an on-site tool room and unique molding processes; we have a very successful track record of using existing tools transferred from other foundries. AMT can solve your casting issues while also saving you time and money!