Our Journey

Our origin:

Incorporated in October 1961, AMT was located in East Northport on Long Island, NY. We originally focused on Explosive Forming before transitioning to Investment Castings in 1969. With steady and solid growth of its investment casting business over the years, in 1990, AMT relocated to its current location in Sharon Springs, NY to better support the growth of its customer base.

Expansion:

As business grew, the building was expanded and equipment purchased to support increasing volume and casting complexity. Recently, AMT invested in additional state of the art equipment including a new wax room with semi-automatic presses, a  100% robotic shelling expansion, and a high speed infrared shell drying tunnel which is unique in the USA. We also acquired a digital X-Ray unit, the best-in-class rapid prototyping 3D wax printer and the only High Speed Automated Visual Inspection machine in the foundry industry.

100% robotic shelling expansion, and a high speed infrared shell drying tunnel which is unique in the USA. We also acquired a digital X-Ray unit, the best-in-class rapid prototyping 3D wax printer and the only High Speed Automated Visual Inspection machine in the foundry industry.

In addition, we implemented a fully integrated ERP system providing real-time shop floor feedback, certified our Quality system under AS9100D and ISO 9001:2015 and achieved NADCAP FPI accreditation.

These investments combined with the dedication of our Team enables us to best meet our customer’s exacting requirements.

Today:

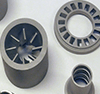

Known for its Quality, Service and Expertise, AMT is a leading manufacturer of Precision Investment Castings used in the Aerospace, Power Generation, Medical, Industrial and Defense markets. Additionally we make Aerospace Fasteners per standards NAS1193, AS14227, MS14198.

With its own on-site tool room and two distinct molding processes AMT has a proven ability to accept transfer tools. So whether you are looking to source a new casting or to solve issues with an existing casting, AMT offers Investment Casting Solutions